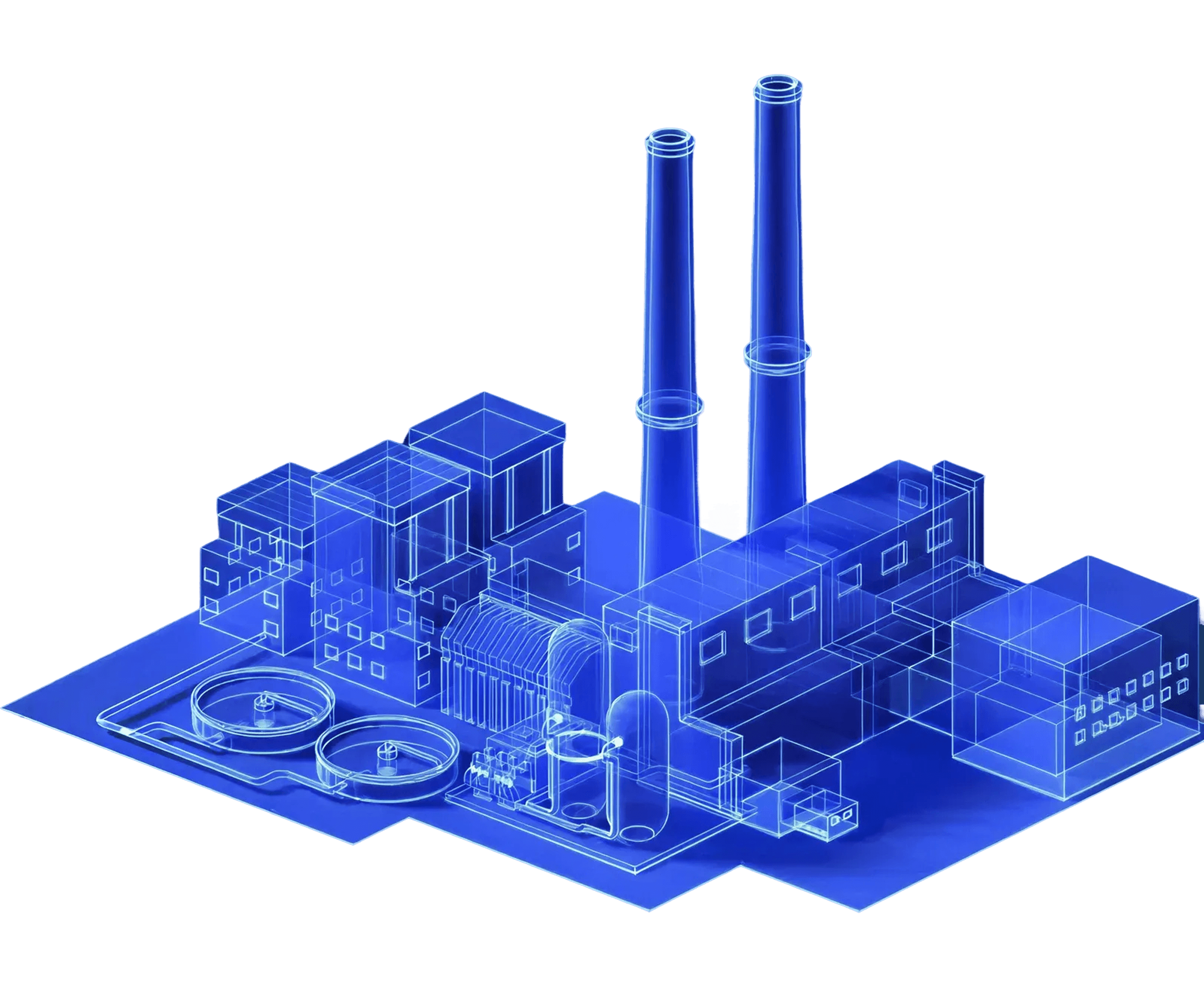

Mirror your physical operations in software to predict, simulate, and optimize performance. Connect once, model fast, automate everywhere.

A Digital Twin Platform gives you a real-time, living view of your operations helping you predict issues, validate decisions, optimize performance, and continuously improve with AI-backed intelligence.

Connect machines, IT/OT & business systems into a one model.

Edge-first architecture, role-based access, and full audit trails.

Drive work orders, set-points, and alarms directly from the twin.

Higher OEE, lower downtime, energy & faster time - to value.

Digital Twins for Your Industry

Built to adapt across industries, our AI-driven platform reduces errors, strengthens decision-making, and streamlines execution for operations of every size and complexity.

Our system links physical operations to digital twins, enabling real-time control and optimization. This boosts efficiency, ensures adaptive responses, and maximizes performance.

Edge gateways ingest OT, IoT, BMS, EMS, and IT systems into a time-aligned stream.

Map assets, processes, and KPIs into a semantic graph with versioned templates.

Run what-if scenarios using physics + ML models to test policies and designs.

Close the loop with set-points, schedules, and automated work orders.